Keywords

Tribology, bearing, lubrication, texturation, Reynolds, EHD, fluid dynamics, elastohydrodynamic, viscosity

Context / Goal

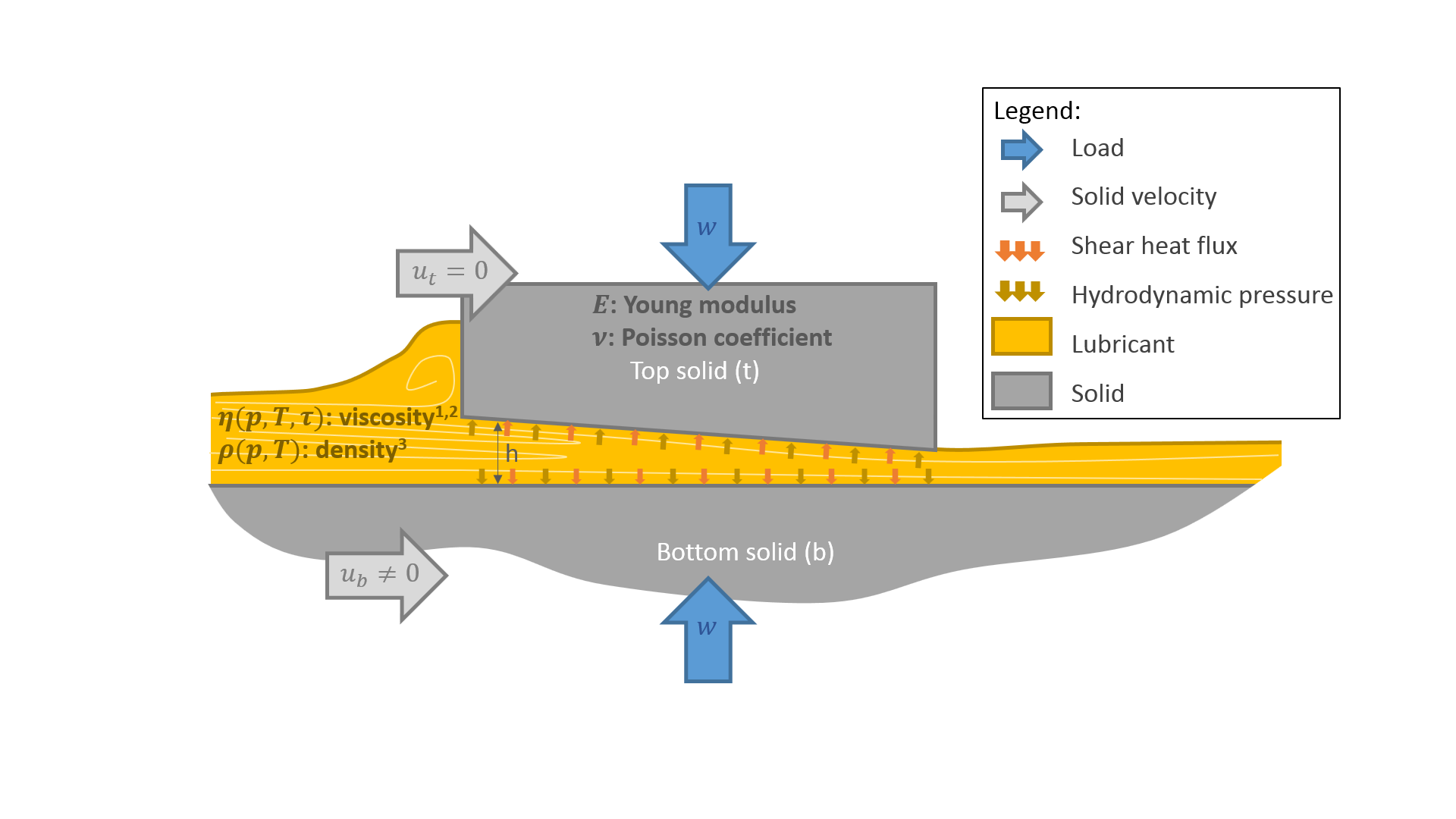

Well-designed lubrication systems can be found in any existing car or industry machinery. Unfortunately, designing a new lubricated interface can be challenging and predicting friction and film thickness prior to fabrication is mandatory. Whereas the trial and error approach is a reliable method, numerical predictions are much less time and money consuming. However, the latter predictions require a complex model.

To solve this problem, SIMTEC managed to make a powerful model available to other people than the numerical experts. Within a user-friendly interface, it is possible to configure the slider bearing operating conditions and the lubricant properties in order to obtain numerical predictions.

SIMTEC's Achievements / Results

A finite element model of the sliding bearing is developed. It can take into account most of the effects able to influence film thickness and friction force :

- Solids geometry;

- Thin film flow (whether the fluid is iso-viscous or piezo-viscous, incompressible or compressible and Newtonian or non-Newtonian) through Reynolds equation and appropriate constitutive relations;

- Solids linear deformations;

- Heat dissipation through the heat equation;

- Basic solid surface textures.

The application allows the user to select the desired geometry and the effects that should be included. After solving, the required graphs are displayed to provide the results of the computation.

Feel free to contact us for a free trial and experience what SIMTEC can do for you !