Keywords

static furnace, resistive furnace, heating, heat transfer, forced convection, natural convection, radiation

Context / Goal

Because of its ability to quickly and efficiently heat a material without contact, induction heating offers an appropriate technological solution to many industrial problems. Here we are interested in modeling an induction furnace in the casting industry context. The modeling of the process permits precise description of the current and temperature distribution in each component of the furnace. SIMTEC can then address different client needs, for example:

-

to optimize the geometry of the furnace component (crucible and coil position, number of turns, etc.) to ensure a complete melting of the material,

-

to optimize the efficiency to limit energy consumption,

-

to size the electric generator, and

-

to respect the safety standards concerning the residual external electromagnetic field (see Modeling and Optimizing Electromagnetic Shielding with COMSOL Multiphysics®).

SIMTEC's Achievements / Results

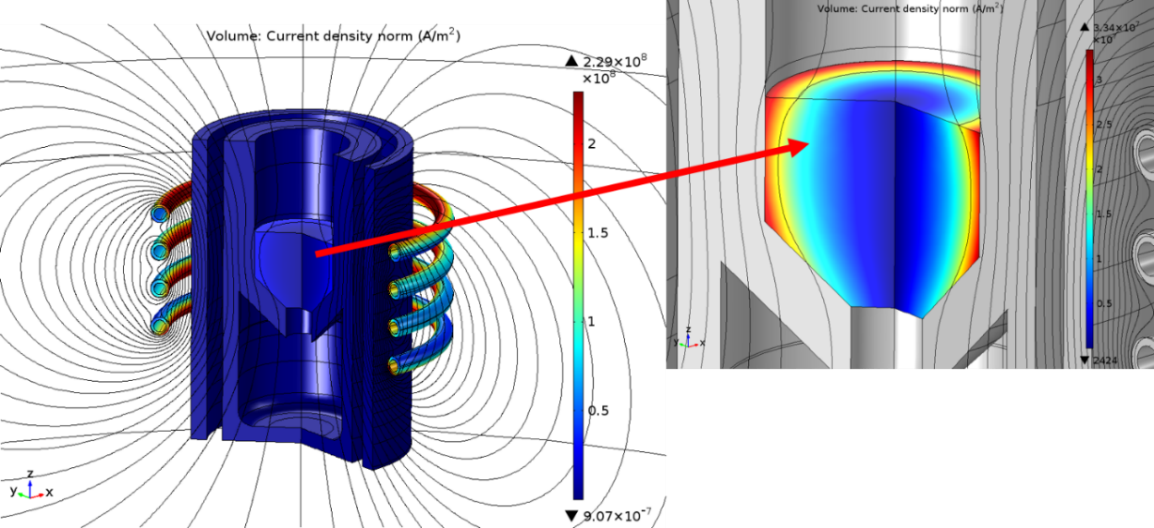

For confidentiality reasons, only numerical results obtained with a simplified model are illustrated here. This model is composed of an inductor with four water-cooled coils, a ceramic heat shield, a graphite crucible and a steel charge. A generator supplies power to the inductor via alternating current. A variable magnetic field is thus generated that induces currents in surrounding conductive components as shown below:

Because of the Joule effect, heat is generated in the furnace. Radiative heat transfers are dominant in this type of application and are taken into account in COMSOL Multiphysics®. The resulting temperature distribution obtained at stationary state is illustrated here:

Parametric studies concerning the electrical properties (power, frequency) or the different component sizes are performed by SIMTEC to optimize the process and to address client needs.