Keywords

Casting, induction, heat transfer, fluid mechanics, turbulence, dimensional analysis

Context / Goal

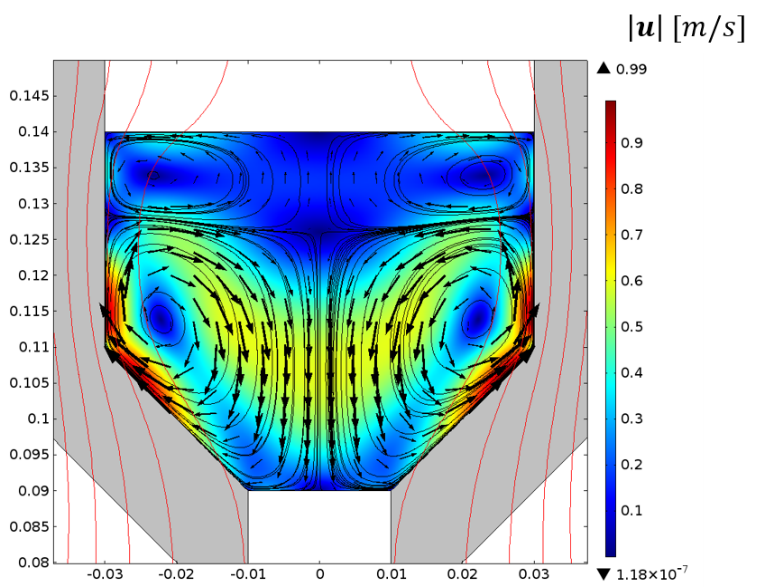

In order to ensure a satisfactory homogeneity of the melt and to increase the life of furnace crucibles, the electromagnetic stirring phenomenon is often used in induction heating processes. Indeed, when a conductive fluid is subjected to an electromagnetic field, a force composed of a repulsive part (magnetic pressure) and a rotational part (stirring) is generated. It produces a movement of the liquid metal that can be controlled to optimize the melting process and ensure the best state after solidification.

SIMTEC is involved in the modeling of this strongly coupled problem in order to determine the resulting velocity field in the melt.

SIMTEC's Achievements / Results

Given the number of physical phenomena and their strong coupling, several steps are required to validate the model "step by step":

-

validation of the material properties constituting the oven with a simplified approach that does not take into account hydraulic effects

-

dimensional analysis to simplify the problem and its resolution (Reynolds number, magnetic Reynolds number, Prandtl number)

-

resolution of the hydraulic problem by taking into account different turbulence models

-

resolution of the complete problem in a fully coupled way and analysis of the phenomena

The velocity field resulting from electromagnetic stirring is shown here on a simplified geometry for confidentiality reasons. Turbulent effects can play a major role in the behavior of the molten metal and are taken into account with RANS turbulence models of the COMSOL Multiphysics® software.

Because of its experience in this domain, SIMTEC offers its numerical expertise to enable the resolution of strongly coupled problems and their validation (mesh convergence, solvers optimization, type of turbulence model, etc.)