Keywords

electrolysis, fluoride production, gas evolution, bubbling, convection, anode, cathode, Joule effect, electrolyte, fluor

Context / Goal

High and low temperature electrolysis processes can be used for the production of industrial gases. These gases are formed at the surface of the electrodes by decomposition of the electrolyte after a current is applied to the cell. This production is accompanied by convective motions due to gas bubbling in the electrolyte and by heat release from the Joule effect and electrode over-potentials. A correct management of the cell requires controlling electrical, thermal and hydraulic aspects, which are all strongly coupled to each other. Multiphysics modeling of the cell is an effective tool to get both quantitative and qualitative knowledge of the process and to optimize the cell operation.

The present case is dedicated to an electrolysis reactor for the production of fluoride gases including a cooling system. The objective is to calculate, for a given electrolysis current:

-

the intensity of the convective motions,

-

the temperature distribution in the electrolytic bath.

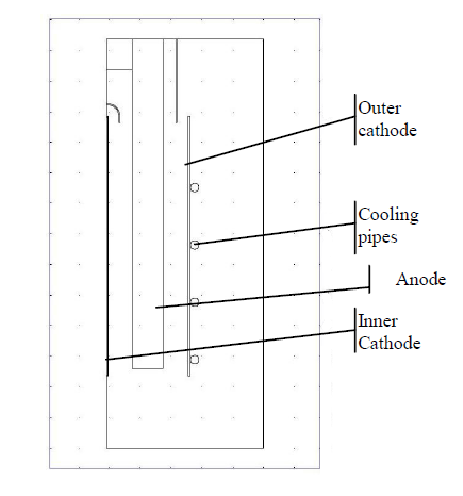

2D model of the electrolysis reactor

SIMTEC's Achievements / Results

The cell is described in a 2D geometry. The different physical phenomena are treated as follows:

-

Electrical model: secondary distribution with Butler-Volmer kinetics laws. The electrical properties of the system (electrolyte conductivity) depend on temperature. The cell is solicited in potentiostatic mode (control of the potential).

-

Thermal model: heat sources are associated with the Joule effect in the electrolyte and the electrodes, and with the electrode over-potentials. Heat is transported by conduction and convection in the electrolyte.

-

Hydrodynamic model: convective motions are described in the electrolyte by the Navier-Stokes equation in mono-phasic media. The velocity of the rising bubbles at the electrodes are calculated beforehand by a diphasic CFD model (liquid+gas) taking into account the Archimedes‘ force.

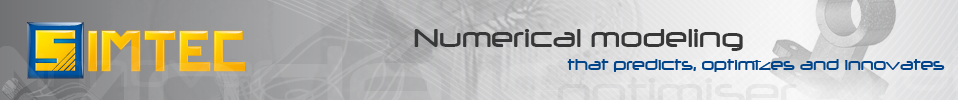

The plot of the local convection velocity in the electrolyte helps to localize positions in the cell where the mass transport is limited. It was noticed that motions are mainly concentrated around the anode which releases gas bubbles.

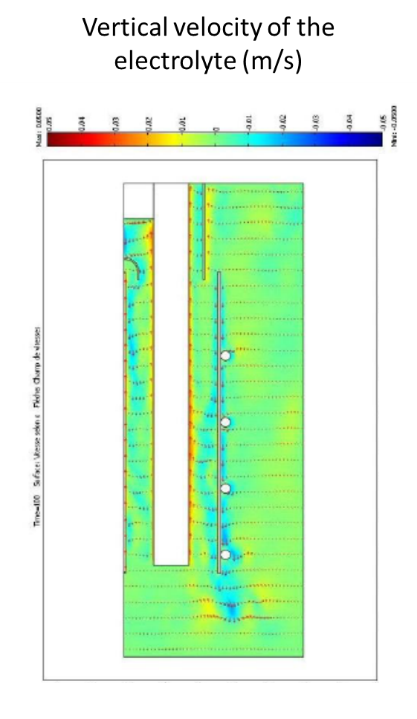

The plot of the temperature field shows that heat release mostly appears between the anode and the central cathode of the device (to the left in the 2D geometry). This model allowed the prediction of the average temperature in the electrolyte as a function of the applied current, in order to predict the maximum current range that is acceptable from a thermal point of view.