Keywords

chemical engineering modeling, chemical reaction, Arrhenius law, computational fluid dynamics, porous medium, catalyst, heat transfer, catalytic bed

Context / Goal

ADISSEO is a worldwide leader in animal nutrition. Their nutritional supplements offer a great safety guarantee for people and the environment while also improving the performance of animal production.

One of their nutritional supplements is methionine, which is produced thanks to acrolein.

Acrolein synthesis started in the mid-20th century. Initially, progress had been realized through experimental feedback. However, at the present time, a more quantitative approach, based on chemical and physical underlying phenomena, needs to be used for the greatest efficiency.

Therefore, ADISSEO asked SIMTEC to develop a numerical model with COMSOL Multiphysics®. This model takes into account a thermal-chemical-fluid flow coupling inside the chemical reactor, in order to obtain a « virtual prototype » and then to maximize its efficiency.

SIMTEC's Achievements / Results

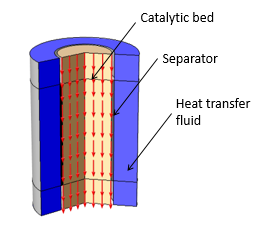

The first mission of SIMTEC was to visit the CLIENT on-site, to discuss the modeling assumptions and the chemical kinetics. An efficient numerical strategy was defined with the CLIENT: first, solving the fluid flow inside the heat transfer fluid, then solving what happens in the catalytic bed (chemistry, CFD in porous medium and heat transfer).

The study consists of developing a numerical model with COMSOL Multiphysics® coupling:

-

the fluid flow of the heat transfer fluid,

-

the gas flow in the catalytic bed,

-

exothermic chemical reactions with complex kinetics (Arrhenius law).

This model was validated through a comparison with more than 10 experimental results.

After this validating step, a comprehensive numerical analysis has been performed to investigate the influence of some bed properties. This model enables us now to consider new ways to optimize the reactor.

This page has been published with the kind authorization of ADISSEO